Work instructions for production are detailed guidelines outlining step-by-step processes to ensure tasks are performed consistently and efficiently․ They enhance clarity‚ reduce errors‚ and promote safety․

1․1 Definition and Purpose of Work Instructions

Work instructions are standardized procedures that outline step-by-step actions for completing tasks in production․ Their purpose is to ensure consistency‚ efficiency‚ and compliance with quality and safety standards․ They provide clear guidance to employees‚ reduce variability‚ and help maintain productivity while minimizing errors․ Well-crafted work instructions are essential for operational excellence and employee training in production environments․

1․2 Importance of Work Instructions in Production

Work instructions are crucial for ensuring consistency‚ efficiency‚ and compliance in production processes․ They reduce variability‚ minimize errors‚ and enhance safety by providing clear‚ standardized guidance․ Well-structured instructions support employee training‚ improve product quality‚ and ensure adherence to regulatory requirements․ Their implementation fosters accountability‚ streamlines workflows‚ and contributes to operational excellence‚ making them indispensable in modern manufacturing environments․

Key Components of a Work Instruction

A work instruction includes scope‚ structure‚ and required details to ensure clarity and compliance․ It outlines processes‚ responsibilities‚ and standards‚ enabling consistent and efficient task execution․

2․1 Scope and Applicability

The scope of a work instruction defines its boundaries‚ specifying the processes‚ tasks‚ and equipment it covers․ Applicability ensures the instruction is relevant to specific roles‚ locations‚ or conditions․ Clearly stating the scope prevents misunderstandings‚ while applicability guarantees the instruction is used correctly․ This section helps identify who is responsible and where the instruction applies‚ ensuring alignment with production goals and standards․

2․2 Structure and Format

A well-structured work instruction follows a standardized format‚ typically including an overview‚ step-by-step procedures‚ and relevant visuals․ Clear headings‚ concise language‚ and numbered lists enhance readability․ The format ensures consistency‚ making it easier for workers to understand and follow the instructions․ Visual aids like diagrams or images can also be incorporated to clarify complex steps and improve comprehension․

2․3 Required Details and Information

Work instructions must include specific details such as materials‚ tools‚ and equipment required․ Safety protocols‚ quality standards‚ and step-by-step procedures should be clearly outlined․ Additionally‚ any necessary precautions‚ inspection points‚ and emergency procedures should be highlighted․ Including visual aids like diagrams or flowcharts can enhance understanding and ensure tasks are performed accurately and safely․

Developing Work Instructions

Developing work instructions involves creating clear‚ step-by-step guides to ensure tasks are executed consistently and efficiently․ Collaboration with subject matter experts is essential for accuracy and relevance․

3․1 Identifying the Need for a Work Instruction

Identifying the need for a work instruction is crucial for ensuring effective production workflows․ This step is triggered by new processes‚ recurring errors‚ or compliance requirements․ Collaboration with stakeholders helps pinpoint gaps‚ while task analysis ensures instructions address specific needs‚ promoting consistency and operational excellence․

3․2 Gathering Information and Resources

Gathering information and resources for work instructions involves consulting with process owners‚ reviewing existing documentation‚ and observing workflows․ This ensures accuracy and relevance․ Collecting data from multiple sources‚ organizing it logically‚ and validating its correctness are essential steps․ Accessible and up-to-date resources help create clear‚ actionable instructions tailored to production needs․

3․3 Writing and Reviewing the Instruction

Writing work instructions requires clarity and precision to ensure tasks are understood and executed correctly․ Use simple language‚ include visual aids‚ and structure the document logically․ Review the instruction with stakeholders to validate accuracy and relevance․ Ensure it aligns with production goals‚ safety protocols‚ and quality standards․ Revisions should reflect feedback and be approved before finalization․

Approving and Distributing Work Instructions

Approval involves stakeholders reviewing instructions for accuracy and relevance․ Distribution ensures accessibility to all staff‚ with clear communication channels for updates and accessibility․

4․1 Approval Process and Stakeholders

The approval process involves stakeholders like quality assurance‚ production managers‚ and safety officers reviewing instructions for accuracy and compliance․ Feedback is collected‚ revisions made‚ and final approval granted before distribution․ This ensures instructions are clear‚ safe‚ and aligned with production goals․

4․2 Distribution Channels and Accessibility

Work instructions are distributed via digital platforms‚ shared drives‚ or printed materials‚ ensuring accessibility to all relevant staff․ Digital tools allow real-time updates and multi-language support‚ enhancing understanding․ Accessibility features include search functionality and version control‚ ensuring the latest instructions are easily retrievable․ This promotes efficiency and compliance across the production floor․

Implementing Work Instructions on the Production Floor

Implementation involves training staff‚ monitoring adherence‚ and providing feedback to ensure compliance․ Clear communication and accessible resources are key to successful execution and continuous improvement․

5․1 Training and Awareness for Staff

Training and Awareness for Staff is essential to ensure staff understand and effectively follow work instructions․ Interactive methods like workshops and hands-on sessions‚ combined with visual aids‚ enhance comprehension․ Regular updates and feedback loops keep the team informed and aligned with any changes․ This approach fosters a culture of efficiency‚ safety‚ and continuous improvement in production processes‚ reducing errors and ensuring consistency․

5․2 Monitoring Compliance and Adherence

Monitoring compliance and adherence ensures that work instructions are followed accurately and consistently․ This involves regular audits‚ checklists‚ and performance metrics to track adherence․ Supervisors and quality teams review processes to identify deviations and address them promptly․ Technology tools‚ such as digital tracking systems‚ can enhance monitoring efficiency․ Continuous feedback loops help maintain high standards‚ ensuring production processes remain aligned with established guidelines and safety protocols․

5․3 Providing Feedback and Corrective Actions

Providing feedback and corrective actions is essential for improving adherence to work instructions․ Supervisors and quality teams conduct regular audits and use checklists to identify deviations․ Feedback is shared through one-on-one sessions or team meetings‚ outlining specific issues and solutions․ Corrective actions‚ such as additional training or process adjustments‚ are implemented to address gaps‚ ensuring compliance and enhancing overall production quality and safety standards․

Safety Protocols in Production Work Instructions

Safety protocols in production work instructions outline procedures to prevent incidents and ensure a safe working environment․ They include hazard assessments‚ PPE requirements‚ and emergency response plans‚ ensuring compliance with safety standards and regulations to protect workers and equipment during production processes․

6․1 Safety Procedures and Precautions

Safety procedures in production work instructions detail essential precautions to minimize risks․ They include the use of personal protective equipment (PPE)‚ proper handling of hazardous materials‚ and emergency exit routes․ Precautions also cover equipment startup checks‚ lockout/tagout procedures‚ and adherence to safety signs․ These measures ensure compliance with industry standards‚ protecting workers and preventing accidents during production processes․

6․2 Emergency Response Plans

Emergency response plans outline procedures for handling production-related incidents like fires‚ spills‚ or equipment failures․ They include evacuation routes‚ emergency contact lists‚ and first aid protocols․ These plans ensure quick‚ coordinated actions to minimize risks and protect personnel․ Regular drills and training are essential to prepare staff for potential emergencies‚ ensuring a swift and safe response․

Quality Control and Assurance

Quality control and assurance ensure products meet specified standards through systematic inspections and testing․ They involve the entire production team to maintain consistency and reliability․

7․1 Quality Standards and Specifications

Quality standards and specifications define the expectations for production outputs‚ ensuring consistency and reliability․ They outline measurable criteria‚ tolerances‚ and requirements for materials‚ processes‚ and finished products․ Adherence to these standards minimizes defects‚ ensures compliance with regulations‚ and maintains customer satisfaction․ Clear documentation of specifications helps production teams understand and meet quality goals effectively․

7․2 Inspection and Testing Procedures

Inspection and testing procedures ensure products meet quality standards by identifying defects early․ These procedures include visual checks‚ measurements‚ and functional tests using calibrated tools․ Documentation of results is crucial for traceability and compliance․ Regular inspections help maintain consistency‚ while testing validates product performance․ This systematic approach minimizes defects‚ ensuring reliable and safe outputs that align with customer expectations and regulatory requirements․

Maintenance and Update of Work Instructions

Regular reviews and audits ensure work instructions remain relevant and accurate․ Updates incorporate feedback and process changes‚ maintaining production efficiency and compliance over time․

8․1 Regular Reviews and Revisions

Regular reviews of work instructions ensure accuracy and relevance․ Revisions incorporate feedback‚ process changes‚ and new requirements‚ maintaining compliance and efficiency․ Scheduled audits and version control systems help track updates‚ ensuring all teams access the latest documents․ This iterative process guarantees that instructions evolve with production needs‚ reducing errors and improving overall performance․

8․2 Document Control and Version Management

Document control ensures that work instructions are managed systematically‚ with version tracking to prevent outdated information․ Version management involves assigning unique identifiers and change logs to monitor updates․ Access controls guarantee only authorized personnel can modify documents‚ maintaining consistency and compliance․ Automated tools often support this process‚ ensuring all teams use the most current and approved instructions effectively․

Tools and Technology for Work Instructions

Digital platforms and specialized software enable efficient creation‚ management‚ and distribution of work instructions; Automation tools integrate seamlessly with production systems‚ enhancing accuracy and streamlining workflows effectively․

9․1 Digital Platforms and Software

Digital platforms and software provide advanced tools for creating‚ managing‚ and distributing work instructions․ These solutions offer features like templates‚ real-time collaboration‚ and version control․ They integrate with production systems‚ enabling seamless updates and access․ AI-powered tools enhance efficiency by automating tasks and providing insights․ Cloud-based platforms ensure accessibility and scalability‚ while mobile apps allow workers to access instructions on the go‚ improving productivity and compliance․

9․2 Automation and Integration with Production Systems

Automation and integration with production systems streamline workflows by linking work instructions to machinery and software․ This ensures real-time data synchronization and reduces manual errors․ Integration with MES and ERP systems enhances operational efficiency․ Automated workflows also enable dynamic updates‚ improving adaptability․ Machine learning algorithms can optimize processes based on historical data‚ fostering continuous improvement and alignment with production goals․

Best Practices for Effective Work Instructions

Effective work instructions require clarity‚ simplicity‚ and visual aids․ Use clear language‚ concise steps‚ and visuals to enhance understanding․ Regularly update and seek feedback to improve accuracy and relevance․

10․1 Clarity and Simplicity in Language

Clarity and simplicity in language are essential for effective work instructions․ Use straightforward terminology‚ avoid jargon‚ and ensure steps are easy to understand․ Break complex tasks into clear‚ concise steps․ Avoid ambiguity by providing specific details․ Use active voice and ensure instructions are free from errors․ Clear language reduces errors‚ enhances efficiency‚ and ensures safety and compliance in production processes․

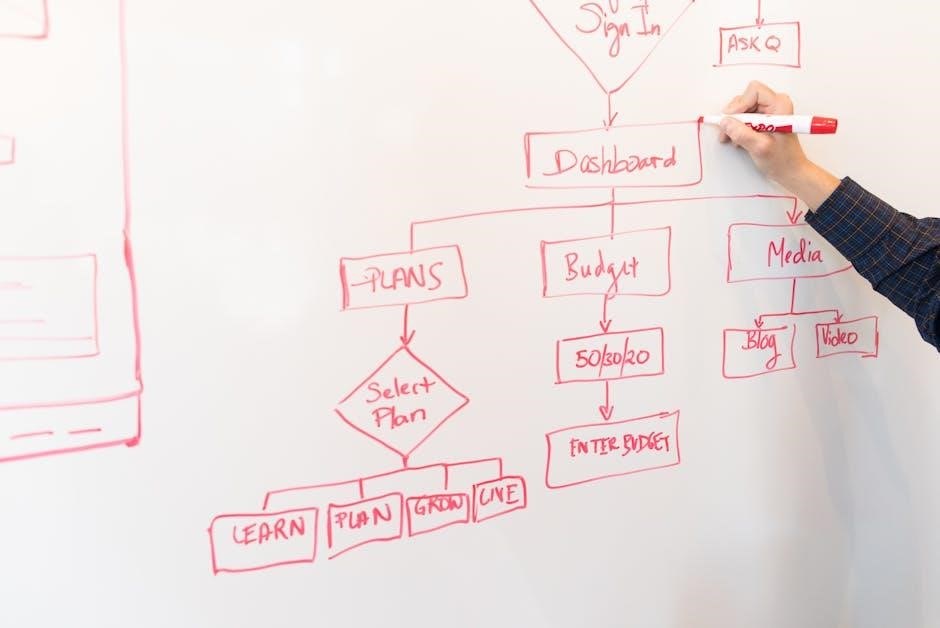

10․2 Use of Visual Aids and Diagrams

Visual aids and diagrams are essential for enhancing understanding in work instructions․ They simplify complex tasks‚ reduce ambiguity‚ and improve task accuracy․ Use diagrams‚ flowcharts‚ and images to illustrate steps‚ tools‚ and equipment․ Visuals make instructions accessible to diverse learners‚ reduce errors‚ and enhance compliance․ They are particularly useful for complex production processes‚ ensuring clarity and efficiency in task execution․

Common Challenges and Solutions

Common challenges include ambiguities‚ outdated information‚ and resistance to changes․ Solutions involve clear language‚ regular updates‚ and training to ensure understanding and compliance with instructions․

11․1 Addressing Ambiguities and Confusions

Addressing ambiguities requires clear‚ concise language and visual aids like diagrams to simplify complex steps․ Regular reviews with stakeholders ensure instructions are unambiguous․ Training sessions and feedback loops help clarify confusions‚ promoting better understanding and adherence to procedures‚ ultimately improving efficiency and reducing errors in production processes․

11․2 Managing Changes and Updates

Managing changes and updates in work instructions requires a structured process․ This includes version control‚ stakeholder reviews‚ and clear communication․ Updates should be documented‚ approved‚ and distributed promptly․ Training sessions ensure staff adapt to new procedures․ Digital tools can automate updates and notifications‚ ensuring compliance and minimizing disruptions in production workflows․

12․1 Summary of Key Points

Work instructions for production are essential tools for ensuring consistency‚ efficiency‚ and safety․ They provide clear‚ step-by-step guidance‚ reducing errors and enhancing compliance․ By outlining roles‚ responsibilities‚ and procedures‚ they streamline processes and promote continuous improvement․ Regular updates and effective implementation are crucial for maintaining relevance and operational excellence in production environments․

12․2 Future Trends in Work Instructions for Production

Future trends in work instructions for production include the integration of advanced technologies like AI‚ AR‚ and IoT for real-time guidance․ Digital platforms will streamline processes‚ while automation will enhance efficiency․ Personalized‚ interactive instructions and predictive maintenance will become standard‚ ensuring safer and more adaptable production workflows․ These innovations will drive compliance‚ reduce downtime‚ and foster continuous improvement in manufacturing environments․

Leave a Reply

You must be logged in to post a comment.