Billboard Bluetooth Speaker Instructions: A Comprehensive Guide

This guide provides detailed instructions for your Billboard Bluetooth speaker, covering setup, operation, troubleshooting, and care for optimal performance and enjoyment.

Understanding Your Billboard Bluetooth Speaker

Your Billboard Bluetooth speaker is designed for portable audio enjoyment, featuring wireless connectivity and a built-in LED disco light for enhanced ambiance. This speaker allows you to stream music from smartphones, tablets, and other Bluetooth-enabled devices. It also offers auxiliary input for wired connections.

Key features include easy-to-use controls for power, mode selection, and volume adjustment. The integrated microphone enables hands-free calling. Understanding these core functionalities will ensure a seamless user experience. The BB2732 model, like others, prioritizes convenience and quality sound, making it ideal for parties, travel, or everyday listening. Refer to the manual for specific model details.

Unboxing and Initial Inspection

Carefully remove your Billboard Bluetooth speaker from its packaging. Inspect the box for any signs of damage during shipping. Inside, you should find the speaker unit itself, a charging cable (likely USB), and this user manual.

Visually inspect the speaker for any physical defects, such as scratches or dents. Ensure all ports (AUX input, charging port) are free from obstruction. Before first use, it’s recommended to fully charge the speaker. Retain the original packaging for potential returns or warranty claims. Confirm all included accessories match the packing list to ensure a complete product.

Powering On and Off

To activate your Billboard Bluetooth speaker, locate the Power On/Off button – typically found on the top or side panel. Press and hold this button for approximately 5 seconds until you hear an audible power-on chime or see the LED indicator illuminate. The speaker is now ready for pairing or operation.

To deactivate the speaker, again, press and hold the Power button. Continue holding it until the power-off chime sounds, or the LED indicator turns off. Avoid simply tapping the power button, as this may not fully power down the device. Proper shutdown conserves battery life and ensures stable operation upon next use.

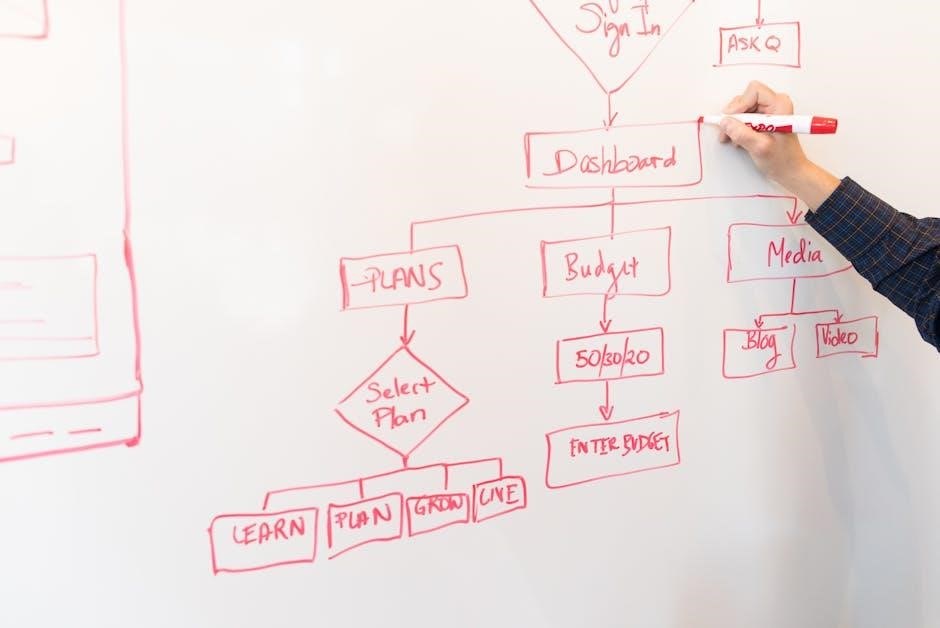

Bluetooth Pairing: Connecting Your Devices

Establishing a Bluetooth connection with your Billboard speaker is straightforward. First, ensure the speaker is powered on. It will often automatically enter pairing mode upon initial power-up, indicated by a flashing blue LED. If not, consult the speaker controls for a dedicated Bluetooth pairing button.

On your smartphone or tablet, activate the Bluetooth feature within the settings menu. Initiate a search for available wireless devices. Your Billboard speaker should appear in the list of discovered devices – typically identified by its model number. Select the speaker to initiate pairing. You may be prompted to enter a passcode (usually “0000” if required).

Activating Bluetooth on Your Smartphone/Tablet

To connect your Billboard speaker, begin by activating Bluetooth on your smartphone or tablet. The process varies slightly depending on your device’s operating system. For iOS devices (iPhones, iPads), navigate to the “Settings” app, then tap “Bluetooth.” Toggle the Bluetooth switch to the “On” position.

Android users should access the “Settings” app, then locate and tap “Connections” or “Bluetooth.” Ensure the Bluetooth switch is turned on. Your device will automatically begin scanning for available Bluetooth devices within range. Refer to your device’s user manual for specific instructions if needed, as menu layouts can differ.

Searching for Available Devices

Once Bluetooth is enabled on your smartphone or tablet, it will automatically initiate a search for nearby Bluetooth devices. Ensure your Billboard speaker is powered on and in pairing mode – typically indicated by a flashing blue light. Your device will display a list of detected devices.

Locate “Billboard BB2732” or a similar name identifying your speaker within the list. The speaker will show on the list of available devices. If the speaker doesn’t appear immediately, ensure it’s close to your device and refresh the device list. Avoid connecting to unknown devices for security reasons.

Successful Pairing Confirmation

Upon selecting your Billboard speaker from the list of available devices, your smartphone or tablet may prompt you for a pairing code. If requested, enter “0000” (four zeros) – this is the standard default code for many Bluetooth devices. A successful pairing is usually confirmed by a change in the speaker’s indicator light, often transitioning from flashing to a solid blue.

Your device will also indicate a successful connection, typically displaying “Connected” next to the speaker’s name; You are now ready to enjoy audio wirelessly! If pairing fails, repeat the process, ensuring the speaker is in pairing mode and no other devices are interfering.

Speaker Controls and Functions

Your Billboard Bluetooth speaker features intuitive controls for seamless operation. The Power button initiates startup (holding for 5 seconds) and shutdown (holding). A dedicated Mode button allows cycling through available input sources – Bluetooth, AUX, and potentially others depending on the model. Volume is adjusted via dedicated “+” and “-” buttons, providing precise control over your listening experience.

Short presses of the Mode button switch between connection types. Familiarize yourself with these controls to quickly manage playback and adjust settings. The speaker’s functionality is designed for user-friendliness, ensuring effortless enjoyment of your favorite audio content.

Power Button Operation

The Billboard speaker’s power button is central to its operation. To activate the speaker, firmly press and hold the Power button for approximately five seconds. A visual or audible cue will confirm successful power-on. Conversely, to power down the device, repeat this process – press and hold the Power button for five seconds until the speaker shuts off.

Avoid brief presses, as these typically won’t initiate power cycling. A sustained press is crucial. This method prevents accidental activation and ensures reliable control. Remember this simple procedure for consistent and dependable operation of your Billboard Bluetooth speaker.

Mode Selection (Bluetooth, AUX, etc.)

Your Billboard speaker offers versatile audio input options. To cycle through available modes – including Bluetooth, AUX, and potentially others depending on the model – utilize the ‘Mode’ button. A short, single press of this button will transition the speaker to the next available input source.

Listen for an audible prompt or observe the LED indicator to confirm the currently selected mode. Bluetooth mode enables wireless connectivity, while AUX allows for a wired connection via a 3.5mm audio cable. Experiment with each mode to discover the best listening experience for your needs and preferences.

Volume Control

Adjusting the volume on your Billboard Bluetooth speaker is straightforward. Dedicated ‘Volume Up’ and ‘Volume Down’ buttons are typically located on the speaker’s control panel. Pressing these buttons incrementally increases or decreases the audio output level.

Some models may also support volume control directly from your connected device (smartphone, tablet, etc.). Be mindful of both the speaker’s volume and your device’s volume to achieve the desired sound level. Avoid excessively high volumes to prevent distortion and potential hearing damage. Start with a low volume and gradually increase it to a comfortable level.

Audio Input Options

Your Billboard Bluetooth speaker offers versatile audio input options to cater to various devices and preferences. Primarily, it supports wireless connectivity via Bluetooth, allowing seamless streaming from smartphones, tablets, and laptops; Beyond wireless, a traditional AUX input (3.5mm audio jack) provides a wired connection for devices lacking Bluetooth capability.

Certain models may also include a Microphone input, enabling karaoke or public address functionality. Switching between these input modes is usually achieved by pressing a dedicated ‘Mode’ button on the speaker. This flexibility ensures compatibility with a wide range of audio sources.

AUX Input Connection

To connect via the AUX input, locate the 3.5mm audio jack on your Billboard speaker. Using a standard 3.5mm audio cable (not always included), connect one end to the speaker’s AUX port and the other end to the headphone or line-out port of your audio source – such as a smartphone, MP3 player, or computer.

Once connected, select the AUX mode on your speaker by pressing the ‘Mode’ button until AUX is indicated. Adjust the volume on both your speaker and the connected device to achieve your desired listening level. Remember that the audio quality depends on the quality of the cable and the source device.

Microphone Functionality

Your Billboard Bluetooth speaker may include a built-in microphone, enabling hands-free calling and voice assistant access. When a call comes in while paired via Bluetooth, the speaker will automatically pause music and route the audio through the microphone and speaker.

To answer a call, briefly press the Power/Play button. To end a call, press the button again. The microphone’s performance depends on proximity and ambient noise. For optimal clarity, position yourself relatively close to the speaker during calls. Some models also support voice assistants; activate them by holding the Power/Play button.

LED Disco Light Features

Many Billboard Bluetooth speakers boast integrated LED disco lights, enhancing the listening experience with vibrant visual effects. These lights typically cycle through various colors and patterns, synchronized or independent of the music. Control options vary; some speakers offer dedicated buttons to toggle the lights on/off, change modes (e.g., color cycling, strobe), or adjust brightness.

Explore different lighting modes to match your mood or party atmosphere. The LED lights are designed for visual enjoyment and do not affect the speaker’s audio performance. Ensure the speaker is placed in an area where the light display can be fully appreciated for maximum impact.

Troubleshooting Common Issues

Encountering problems? Here’s a quick guide. If the speaker won’t power on, verify the charging cable is securely connected and the speaker has sufficient charge. For Bluetooth pairing issues, ensure Bluetooth is enabled on your device and the speaker is in pairing mode. Try forgetting the speaker on your device and re-pairing.

If there’s no sound, check the volume levels on both the speaker and your connected device. Confirm the correct audio source is selected. A factory reset (holding the power button) can often resolve persistent issues. If problems persist, consult the full user manual or contact customer support for further assistance.

Speaker Not Powering On

If your Billboard speaker fails to power on, begin by verifying the charging cable is firmly connected to both the speaker and a functioning power source. Allow the speaker to charge for at least two hours, even if it briefly illuminates. A completely depleted battery may require extended charging time.

Next, attempt to power on the speaker again by pressing and holding the power button for a full five seconds. If it still doesn’t respond, try a different charging cable and power adapter to rule out a faulty accessory. If these steps fail, a factory reset might resolve the issue, though this is less common for a no-power situation.

Bluetooth Pairing Problems

Experiencing difficulty pairing your Billboard speaker? First, ensure Bluetooth is activated on your smartphone or tablet and that the speaker is in pairing mode – typically indicated by a flashing light. Confirm the speaker isn’t already connected to another device; Bluetooth can only maintain one active connection at a time.

If pairing repeatedly fails, try “forgetting” or removing the speaker from your device’s Bluetooth list, then re-initiating the pairing process. Move closer to the speaker during pairing. Interference from other wireless devices can sometimes disrupt the connection. A factory reset of the speaker can also resolve persistent pairing issues.

No Sound Output

If your Billboard speaker isn’t producing sound, begin by verifying the volume level on both the speaker and your connected device. Ensure the speaker isn’t muted; Check the audio source selection; confirm it’s set to Bluetooth if you’re using a wireless connection, or AUX if using a cable.

Try disconnecting and reconnecting your Bluetooth device. Test with a different audio source (music file or app) to rule out a problem with the original source. If using the AUX input, ensure the cable is securely connected at both ends. A factory reset might resolve software glitches causing the sound issue.

Factory Resetting Your Speaker

Performing a factory reset on your Billboard Bluetooth speaker can resolve various operational issues. Typically, this involves pressing and holding the power button for an extended period – often around 5 seconds – until the speaker indicates a reset, usually with an audible tone or flashing lights.

This process clears all saved settings, including paired devices and customized preferences, returning the speaker to its original factory state. Note that specific reset procedures may vary slightly depending on the exact Billboard model. Consult your speaker’s specific manual for precise instructions. After resetting, you’ll need to re-pair your devices.

Speaker Maintenance and Care

To ensure the longevity and optimal performance of your Billboard Bluetooth speaker, regular maintenance is recommended. Clean the exterior with a soft, slightly damp cloth; avoid harsh chemicals or abrasive cleaners. Protect the speaker from extreme temperatures, humidity, and direct sunlight.

Avoid dropping or subjecting the speaker to physical shock. When not in use, store it in a cool, dry place. Regularly check the charging port for debris and clean if necessary. Proper care will help maintain sound quality and prevent potential damage, extending the life of your Billboard speaker.

Warranty Information

Your Billboard Bluetooth speaker is covered by a [Specify Duration ― e.g., one-year] limited warranty against defects in materials and workmanship from the date of original purchase. This warranty does not cover damage resulting from misuse, abuse, accidents, or unauthorized modifications.

To make a warranty claim, please contact our customer support team with proof of purchase. We will, at our discretion, repair or replace the defective product. This warranty gives you specific legal rights, and you may have other rights which vary by location. See our full warranty policy online for complete details and exclusions.

Safety Precautions

To ensure safe operation, avoid exposing the Billboard Bluetooth speaker to extreme temperatures or humidity. Do not disassemble or attempt to repair the speaker yourself, as this will void the warranty and may pose a safety hazard. Keep the speaker away from flammable materials and liquids.

Always use a qualified power adapter and avoid overloading electrical outlets. Prolonged exposure to high volumes may damage your hearing, so listen responsibly. Clean the speaker with a soft, dry cloth; do not use abrasive cleaners. Follow these precautions to enjoy your speaker safely and reliably.

Billboard BB2732 Specific Instructions

For the Billboard BB2732 model, press and hold the power button for five seconds to initiate power on. To power off, maintain pressure on the same button. Activate Bluetooth on your device and search for available wireless connections; the BB2732 will appear in the list. Short press the ‘Mode’ button to toggle between Bluetooth and auxiliary input.

Microphone functionality is integrated, enhancing karaoke or public address capabilities. A factory reset can often be achieved by holding the power button for an extended duration. Refer to the complete user manual for detailed instructions and troubleshooting steps specific to the BB2732;