The AORUS B650M Elite AX is a high-performance micro-ATX motherboard designed for AMD Ryzen 7000, 8000, and 9000 series processors․ It features DDR5 memory support, PCIe 5․0, Wi-Fi 6E, Bluetooth 5․3, and a 5-year warranty for reliability․

1․1 Overview of the Motherboard

The AORUS B650M Elite AX is a micro-ATX motherboard designed for AMD Ryzen 7000, 8000, and 9000 series processors․ It offers robust features like DDR5 memory support, PCIe 5․0, and Wi-Fi 6E connectivity․ The board includes advanced thermal solutions, dual M․2 slots, and high-speed USB ports․ With a focus on durability and performance, it is ideal for both gamers and content creators seeking a compact yet powerful system․

1․2 Key Features and Specifications

The AORUS B650M Elite AX features a Twin 12+2 Phases Digital VRM Solution for stable power delivery․ It supports DDR5 memory with AMD EXPO and Intel XMP profiles for enhanced performance․ The motherboard includes PCIe 5․0 x4 and PCIe 4․0 x4 M․2 connectors for fast storage; It also has SATA 6Gb/s ports, Wi-Fi 6E, Bluetooth 5․3, and a 2․5GbE LAN for reliable connectivity․ A 5-year warranty ensures long-term reliability․

Processor and Socket Compatibility

AMD Socket AM5 supports Ryzen 7000, 8000, and 9000 series processors, offering compatibility with the latest AMD CPUs and advanced platform features․

2․1 AMD Socket AM5 Support

The AORUS B650M Elite AX features AMD Socket AM5, enabling compatibility with Ryzen 7000, 8000, and 9000 series processors․ This socket supports cutting-edge AMD CPUs, delivering enhanced performance, PCIe 5․0, and DDR5 capabilities for next-generation computing․ Designed for micro-ATX builds, it ensures seamless integration of modern AMD processors with advanced platform features for optimal functionality and future-proofing․

2․2 Compatibility with Ryzen 7000, 8000, and 9000 Series Processors

The AORUS B650M Elite AX is fully compatible with AMD Ryzen 7000, 8000, and 9000 series processors, offering exceptional performance and versatility․ It supports DDR5 memory with AMD EXPO profiles for enhanced overclocking and stability․ This compatibility ensures users can leverage the latest CPU technologies, including PCIe 5․0 and high-speed connectivity, for a powerful and future-proof computing experience․

Performance and Power Delivery

The AORUS B650M Elite AX features a Twin 12+2 Phases Digital VRM Solution, ensuring stable power delivery and optimal performance for demanding workloads and overclocking scenarios․

3․1 Twin 12+2 Phases Digital VRM Solution

The AORUS B650M Elite AX is equipped with a Twin 12+2 Phases Digital VRM Solution, offering precise power delivery and enhanced stability for AMD Ryzen 7000, 8000, and 9000 series processors․ This advanced design ensures consistent performance under heavy workloads and overclocking scenarios, utilizing high-quality MOSFETs, drivers, and capacitors․ The digital VRM provides dynamic voltage regulation, minimizing heat and maximizing efficiency for both gaming and productivity tasks․

3․2 DDR5 Memory Support with AMD EXPO and Intel XMP Profiles

The AORUS B650M Elite AX supports DDR5 memory with AMD EXPO and Intel XMP profiles, enabling high-speed performance and overclocking capabilities․ Dual-channel memory support allows for enhanced bandwidth, while AMD EXPO and Intel XMP profiles optimize memory settings for AMD and Intel processors, respectively․ This ensures stable, high-performance memory operation, perfect for gamers and content creators seeking reliable and fast system responsiveness․

Storage and Expansion Options

The AORUS B650M Elite AX offers versatile storage solutions, including PCIe 5․0 x4 and PCIe 4․0 x4 M․2 connectors, alongside SATA 6Gb/s ports for traditional drives․ This ensures fast storage options and compatibility with modern NVMe SSDs, providing ample flexibility for both high-speed and legacy storage needs in a compact build․

4․1 PCIe 5․0 x4 and PCIe 4․0 x4 M․2 Connectors

The AORUS B650M Elite AX features PCIe 5;0 x4 and PCIe 4․0 x4 M․2 connectors, enabling high-speed NVMe SSD support for blazing-fast storage performance․ These connectors support the latest SSDs, delivering sequential read/write speeds of up to 10,000 MB/s, ensuring optimal performance for gaming, content creation, and high-speed data transfers․ The dual M․2 slots provide flexibility for users to configure their storage needs efficiently․

4․2 SATA 6Gb/s Ports for Traditional Storage

The AORUS B650M Elite AX includes four SATA 6Gb/s ports, providing reliable and high-speed connectivity for traditional HDDs and SSDs․ These ports support RAID 0, 1, and 10 configurations, offering flexibility for storage customization and redundancy․ Ideal for users with existing SATA drives, they ensure backward compatibility while maintaining superior data transfer speeds of up to 6 Gbps, catering to both performance and reliability needs․

Thermal and Cooling Design

The AORUS B650M Elite AX features a robust cooling system with a 6mm heatpipe and thermal pads for optimal VRM and M․2 temperature management․

5․1 Advanced Thermal Guard for M․2 Slots

The AORUS B650M Elite AX incorporates an Advanced Thermal Guard to protect M․2 slots from overheating․ This system uses a 6mm heatpipe and high-quality thermal pads to ensure efficient heat dissipation․ It safeguards SSDs from thermal throttling, maintaining optimal performance during intense workloads․ The design enhances cooling efficiency, ensuring prolonged system reliability and stability for demanding applications․

5․2 Robust VRM Cooling with Heatpipe and Thermal Pads

The AORUS B650M Elite AX features a robust VRM cooling system with a 6mm heatpipe and high-quality thermal pads․ These components ensure efficient heat dissipation from the VRM, maintaining stable temperatures during high-performance workloads․ The design minimizes thermal throttling, providing consistent power delivery to the CPU․ This advanced cooling solution enhances overall system reliability and performance, making it ideal for demanding applications and overclocking scenarios․

Connectivity and Networking

The AORUS B650M Elite AX offers Wi-Fi 6E, Bluetooth 5․3, 2․5GbE LAN, and USB 3;2 Gen 2 for high-speed wired and wireless connectivity and data transfer․

6․1 Wi-Fi 6E and Bluetooth 5․3 Support

The AORUS B650M Elite AX features Wi-Fi 6E and Bluetooth 5․3 for enhanced wireless connectivity․ Wi-Fi 6E supports faster speeds, lower latency, and dual-band operation, while Bluetooth 5․3 ensures stable connections for peripherals․ This setup is ideal for high-bandwidth applications and reliable device pairing, making it perfect for modern wireless needs and seamless multitasking․

6․2 2․5GbE LAN for High-Speed Wired Connections

The AORUS B650M Elite AX includes a 2․5GbE LAN port, delivering high-speed wired connectivity․ This feature supports faster data transfer rates, reduced latency, and stable performance for gaming, streaming, and heavy bandwidth tasks․ With Intel’s high-quality LAN chipset, it ensures reliable connections and minimizes interruptions, making it ideal for users seeking consistent and speedy wired networking experiences․

Audio and Visual Features

The AORUS B650M Elite AX features high-quality audio with Realtek CODEC for immersive sound and supports HDMI/DisplayPort for multi-display setups, enhancing both visual and audio experiences․

7․1 High-Quality Audio with Realtek CODEC

The AORUS B650M Elite AX delivers immersive audio with the Realtek CODEC, providing high-fidelity sound for gaming and multimedia․ Its 8-channel audio configuration ensures crystal-clear output, while premium capacitors optimize sound quality and reduce noise․ Designed for audiophiles, it supports 7․1-channel surround sound and features durable audio ports for reliable connectivity, ensuring an exceptional listening experience in any setup․

7․2 HDMI and DisplayPort for Multi-Display Setup

The AORUS B650M Elite AX features HDMI and DisplayPort connections, enabling multi-display configurations for enhanced productivity and immersive gaming․ These ports support high-resolution outputs, ensuring crisp visuals across multiple screens․ With versatile connectivity options, users can easily connect monitors, projectors, or other displays, making it ideal for both work and entertainment environments that require flexible and high-quality visual setups․

Form Factor and Build Quality

The AORUS B650M Elite AX features a micro-ATX form factor, ideal for compact builds, and is built with a durable PCB and ultra-durable components for long-term reliability and stability․

8․1 Micro-ATX Form Factor for Compact Builds

The AORUS B650M Elite AX features a micro-ATX form factor, perfect for compact builds and space-efficient systems․ Its smaller size allows for a more streamlined PC setup without compromising on performance or features․ This form factor is ideal for users seeking a powerful yet compact solution, making it suitable for both home and office environments, offering a balance between power and portability․

8․2 Durable PCB and Ultra-Durable Components

The AORUS B650M Elite AX is built with a durable PCB and ultra-durable components, ensuring long-lasting performance and reliability․ High-quality materials and robust construction provide excellent stability, even under demanding workloads․ The motherboard’s design emphasizes longevity, with components selected for their endurance and ability to withstand the stresses of overclocking and heavy usage, making it a dependable choice for both enthusiasts and everyday users․

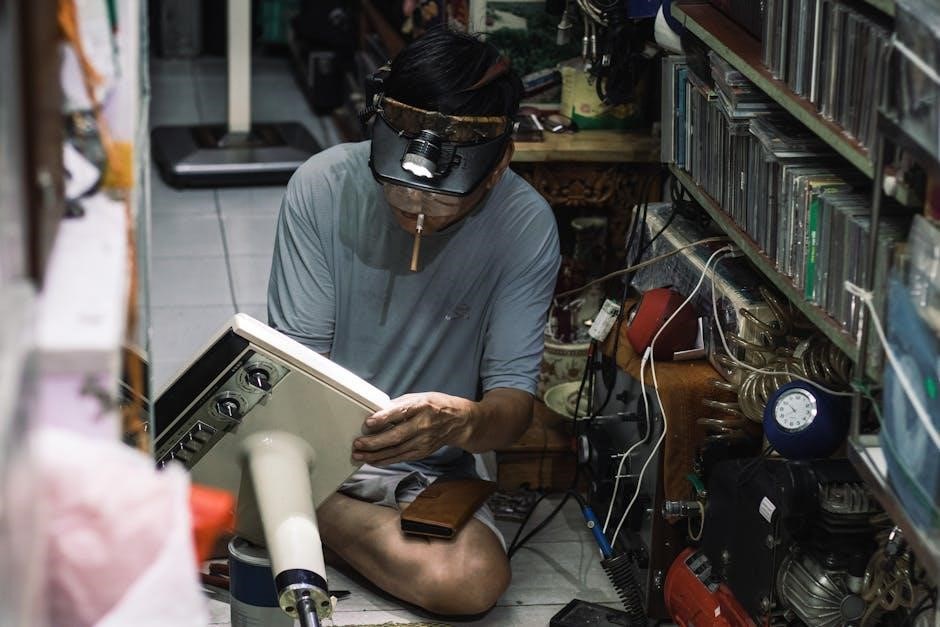

DIY-Friendly Features

The AORUS B650M Elite AX offers DIY-friendly features like EZ-Latch for easy GPU installation and Q-Flash Plus for BIOS updates without a CPU, simplifying customization and upgrades․

9․1 EZ-Latch for Easy GPU Installation

The AORUS B650M Elite AX features the innovative EZ-Latch mechanism, designed to simplify GPU installation and removal without tools․ This user-friendly solution reduces the risk of damaging components and ensures a secure connection, making it ideal for both novice and experienced builders․ The EZ-Latch promotes a hassle-free upgrade experience, aligning with the motherboard’s focus on durability and high-quality construction․

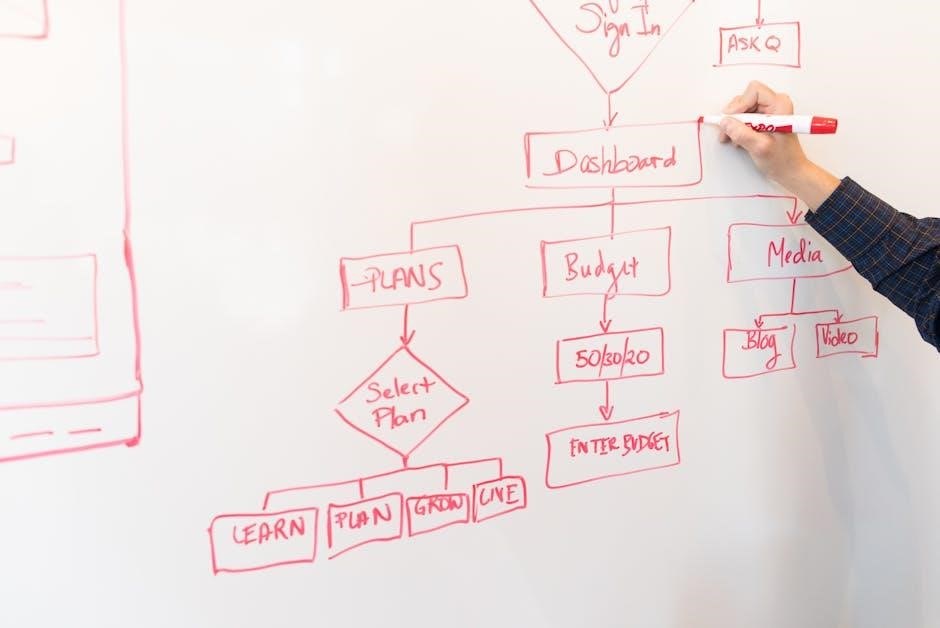

9․2 Q-Flash Plus for BIOS Updates Without CPU

The AORUS B650M Elite AX includes Q-Flash Plus, enabling BIOS updates without requiring a CPU installation․ This innovative feature allows users to flash the BIOS using a USB drive, simplifying the process for builders and upgraders․ It ensures system stability and compatibility with the latest processors, providing a seamless and efficient way to maintain an up-to-date BIOS, even during initial setup or hardware upgrades․

Warranty and Support

The AORUS B650M Elite AX is backed by a 5-year warranty, ensuring long-term reliability and comprehensive customer support for a worry-free ownership experience․

10;1 5-Year Warranty for Long-Term Reliability

The AORUS B650M Elite AX is backed by an extensive 5-year warranty, ensuring durability and reliability for your investment․ This comprehensive coverage includes protection for parts and labor, offering peace of mind for users․ GIGABYTE’s commitment to quality is reflected in this extended warranty, providing assurance for long-term performance and customer satisfaction․

10․2 Comprehensive Customer Support and Resources

GIGABYTE offers extensive customer support and resources for the AORUS B650M Elite AX, ensuring a seamless user experience․ From detailed manuals to 24/7 technical assistance, users gain access to a wealth of online resources, including forums, FAQs, and driver downloads․ The brand also provides direct customer service and warranty support, alongside BIOS update tools like Q-Flash Plus for hassle-free upgrades․