This manual provides a comprehensive guide for troubleshooting‚ diagnosing‚ and repairing GE washers. It includes safety tips‚ repair procedures‚ and maintenance advice to ensure optimal performance and longevity.

Overview of the GE Washer Repair Manual

The GE Washer Repair Manual is a comprehensive guide designed to help users troubleshoot‚ diagnose‚ and repair issues with their GE washing machines. It covers a wide range of topics‚ including electrical safety‚ disassembly procedures‚ and replacement of parts like the motor housing and switch rods. The manual also provides fault codes‚ maintenance tips‚ and instructions for optimizing performance. Available as a downloadable PDF‚ it supports various GE washer models‚ ensuring users have access to detailed technical information for effective repairs and care.

Importance of Following the Repair Manual

Following the GE Washer Repair Manual is crucial for ensuring safety and effective repairs. It provides step-by-step instructions and safety precautions‚ such as electrical safety tips and the Lockout/Tagout process‚ to prevent accidents and damage. Adhering to the manual helps maintain warranty validity and prevents costly mistakes. Proper procedures ensure optimal performance and longevity of the appliance. Always refer to factory-specified parts and guidelines for reliable repairs and to avoid voiding warranties or causing further issues.

Safety Precautions and Guidelines

Adhere to all safety guidelines for safe repairs. Disconnect power before starting work. Use proper tools and wear protective gear. Never bypass safety features or attempt repairs without following the Lockout/Tagout process to prevent accidental start-ups. Ensure all internal components are handled by authorized technicians only.

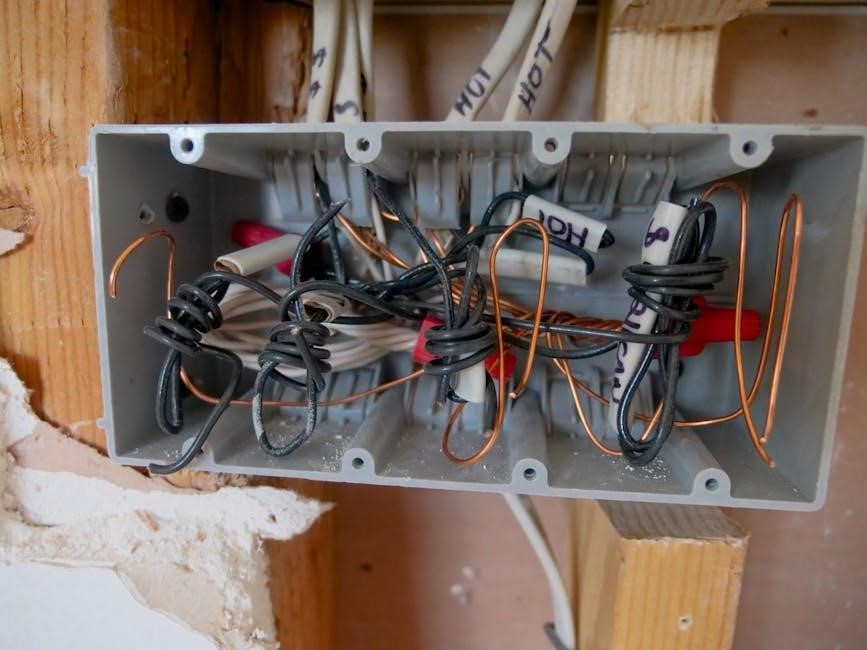

Electrical Safety Tips

Always disconnect the power supply before starting any repair to avoid electric shock. Ensure the mains voltage matches the washer’s specifications. Never bypass safety features or use damaged cables. Replace faulty plugs or cords immediately. Wear insulated gloves and use proper tools to handle electrical components. Avoid overloading circuits‚ as this can cause malfunctions. Keep children away from electrical parts during repairs. Follow the Lockout/Tagout process strictly to prevent accidental start-ups. Only authorized technicians should handle internal electrical systems to ensure safety and compliance with manufacturer guidelines.

Lockout/Tagout (LOTO) Process

Before servicing‚ ensure the washer is shut down and disconnected from power. Isolate all energy sources‚ including electrical‚ water‚ and gas. Apply approved locks and tags to prevent accidental start-ups. Verify energy isolation using appropriate tools.Maintain control of locks and tags until repairs are complete. Only authorized personnel should perform LOTO to ensure safety. This process prevents unexpected machine operation‚ protecting technicians from injury. Always follow GE’s specific LOTO procedures outlined in the manual to guarantee a safe working environment.

Diagnostic and Troubleshooting Guide

Refer to the fault chart for binary display codes. Identify issues by symptoms and error codes. This guide helps locate problems and directs you to repair solutions effectively.

Common Fault Codes and Their Meanings

The GE washer repair manual includes a detailed fault chart with 32 binary display codes. These codes‚ shown via cycle status lights‚ indicate specific issues like motor failure or sensor malfunctions. Understanding these codes helps diagnose problems accurately. For example‚ a specific sequence of lights may signal a faulty lid switch or drain pump issue. Referencing the manual’s fault chart ensures you identify the root cause efficiently. This section is essential for troubleshooting and guiding repairs effectively‚ saving time and ensuring safety. Always cross-reference codes with the manual for precise solutions.

How to Identify Issues with Your GE Washer

Identifying issues with your GE washer starts with observing unusual symptoms‚ such as loud noises‚ leaks‚ or failure to start. Check for error codes displayed on the control panel‚ as these indicate specific problems like faulty sensors or motor issues. Inspect the lid switch‚ drain pump‚ and belts for damage or blockages. Refer to the fault chart in the manual to match symptoms with potential causes. Regularly monitoring performance and addressing issues early prevents major repairs. Always prioritize safety by disconnecting power before investigating internal components.

Repair and Replacement Procedures

Repair and replacement procedures for GE washers involve disassembling the unit‚ identifying faulty parts‚ and replacing them with factory-specified components. Always follow the manual’s instructions for safe and effective repairs.

Disassembling the Washer

Disassembling the GE washer requires careful steps to ensure safety and proper access to internal components. Start by disconnecting power and water supplies‚ then apply the Lockout/Tagout process. Remove the top panel by taking out screws‚ followed by the control panel and switches. Disconnect electrical connectors and hoses carefully. For front-load models‚ remove the door and drum to access the motor and pump. Refer to the service guide for specific torque specifications and diagrams to avoid damaging parts during disassembly.

Replacing Parts: Motor Housing and Switch Rods

Replacing the motor housing (part #315013660) and switch rods involves disconnecting electrical connectors and removing screws. Ensure all power and water supplies are disconnected. Use factory-specified parts to maintain compatibility. For the motor housing‚ carefully lift and align it with mounting brackets. Switch rods require precise alignment to ensure proper functionality. Refer to the technical service guide or Parts Diagram for exact instructions; Always tighten screws to the specified torque to prevent damage. This process ensures optimal performance and longevity of your GE washer.

GE Washer Parts and Accessories

GE washers require genuine parts like factory-specified hoses‚ motor housing‚ and switch rods for optimal performance. Visit Sears Parts Direct or the GE Appliances website for authentic components and manuals.

Factory-Specified Parts and Hoses

Using factory-specified parts ensures compatibility and optimal performance for your GE washer. These parts‚ such as motor housing and switch rods‚ are designed to meet precise specifications. Always refer to the manual for part numbers. Genuine hoses are recommended to prevent leaks and damage. Non-specified parts may void warranties or cause malfunctions. Visit Sears Parts Direct or the GE Appliances website for authentic components. This ensures reliability and maintains your appliance’s longevity‚ avoiding potential risks associated with third-party alternatives.

Where to Find Genuine GE Parts

Genuine GE parts can be found on the GE Appliances website or through Sears Parts Direct. These platforms offer factory-specified components‚ ensuring compatibility and quality. Use your model number to search for specific parts. The GE Appliances site provides part diagrams and installation guides‚ while Sears Parts Direct offers a wide selection of genuine components. Both sources guarantee authenticity‚ ensuring your washer operates efficiently and safely‚ aligning with factory standards for optimal performance and longevity.

Maintenance and Care Tips

Regularly clean filters‚ check hoses‚ and ensure proper installation. Use factory-specified parts to maintain efficiency and performance‚ preventing potential damage and ensuring optimal washer operation.

Regular Maintenance to Prevent Damage

Regular maintenance is essential to prevent damage and ensure optimal performance. Clean the washer’s gasket and drain pump filter monthly. Check hoses for cracks or wear and replace them every 5 years. Ensure the washer is properly balanced to avoid vibration damage. Leave the lid open after use to dry the interior and prevent mold. Avoid overloading the washer‚ as this can strain the motor. Always use factory-specified parts and follow the Lockout/Tagout (LOTO) process before servicing to ensure safety.

Cleaning and Optimizing Washer Performance

Regular cleaning is crucial for optimizing your GE washer’s performance. Run a cleaning cycle with a washer cleaner or vinegar to remove detergent residue and odors. Clean the gasket and drain pump filter monthly to prevent debris buildup. Check and clear blockages in the drain hose and ensure proper ventilation. Avoid overloading the washer‚ as this can reduce efficiency. Use the correct detergent dosage to prevent residue accumulation. For tough odors‚ leave the lid open after use to allow drying. These steps ensure your washer runs efficiently and lasts longer.

Resources for Further Assistance

Visit the GE Appliances website to download PDF manuals‚ access parts diagrams‚ and explore technical service guides for detailed repair instructions and troubleshooting support.

Downloading the GE Washer Repair Manual

To access the GE Washer Repair Manual‚ visit the official GE Appliances website. Enter your washer’s model number to download the PDF manual‚ which includes detailed repair procedures‚ parts diagrams‚ and troubleshooting guides. Additionally‚ websites like Sears Parts Direct offer manuals‚ parts‚ and diagrams for various GE washer models‚ ensuring you find the resources you need for successful repairs.

For specific models‚ such as the GE GTW465ASN2WW‚ the manual provides step-by-step instructions for diagnosing issues like fault codes and replacing components like the motor housing or switch rods. Always ensure to download from trusted sources to avoid counterfeit or incomplete manuals.

Online Platforms for Parts and Manuals

For genuine GE washer parts and manuals‚ visit the official GE Appliances website. Enter your model number to access specific manuals‚ installation guides‚ and parts diagrams. Additionally‚ Sears Parts Direct offers a wide range of GE washer parts and manuals‚ ensuring you find exactly what you need. Websites like ManualsLib and ManualsOnline also provide free downloads for various GE washer models. Always verify the authenticity of the source to ensure accurate and reliable information.

This concludes the GE washer repair manual. By following the guidelines‚ troubleshooting tips‚ and maintenance advice‚ you can ensure your appliance runs efficiently. Use genuine parts and refer to official resources for continued support.

Final Tips for Successful Repair

Always use genuine GE parts to ensure compatibility and maintain warranty. Follow safety guidelines strictly to avoid electrical hazards. Regularly inspect and clean filters to optimize performance. Refer to the official GE repair manual for precise instructions. If unsure‚ consult a certified technician to prevent further damage. Keep the manual handy for future reference and updates. By adhering to these tips‚ you can extend the lifespan of your GE washer and ensure reliable operation.